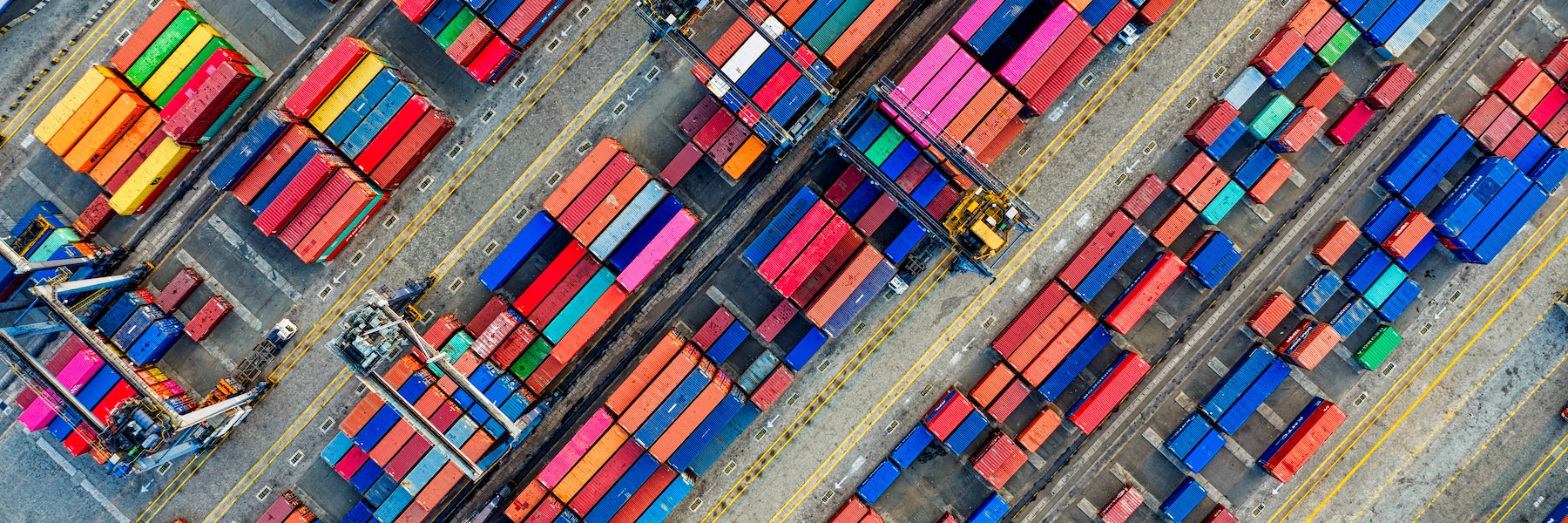

Supply chain complexity is a significant challenge for all importers, especially those importing at higher volumes. Managing and tracking thousands of containers and the inventory in each is a painstaking task.

Multinational global shippers, whether it is a retail company, manufacturer, processed food company or another type of importer, likely have a U.S. import network that uses a wide range of U.S. gateways and distribution centers. Tracking all these containers and what is in them can be time-consuming, costly, and difficult. This is especially true if the importer isn’t using freight technology with real-time visibility and clean data. Additionally, there is a lack of manpower to oversee these complex infrastructures.

Moreover, supply chain professionals can work to mitigate disruptions which are often unplanned and unforeseen. New advancements in technology, led by tech innovators like EDRAY and others, can help bridge theses gaps and provide access to better data and foreseeability to help mitigate problems when they occur reducing massive costs and supply chains disruption.

“Supply chain disruptions seem to happen each and every year. They can come from many different angles, and the hard truth is – most importers do not have the forecasting, visibility tools or sufficient staff to handle them leading to costly delays and fees. Proactive planning for such events is mandatory. says Brett Parker, Chief Commercial Officer for EDRAY.

Savvy managers, though, can take their supply chain organizations to the next level with foresight and strategies like those listed below.

1: Leverage Real Time Data

Reducing expenses such as detention and demurrage, begins with access to real-time data. Knowing where containers are at every node can help spot bottlenecks and potential stoppages ahead of time. Tech visibility platforms alone that focus on end-to-end container management will not work as bad data in equals bad data out. However, cleansed data that is actionable can. It is important to make sure your organization has a partner or the resources to do so on a timely and consistent basis. Destination Management, a new concept, is focused on this exact task. Using a variety of complex data partnerships and integrations along with a team of logisticians can to provide better insight into real-time location of containers as they arrive into ports.

One subject that has been in the spotlight is demurrage and detention charges. These “hidden” costs can escalate into millions of dollars in a one-month period when disruptions occur. Many importers are finding that they lack visibility to container operations at marine terminals, which makes managing their inbound containers extremely difficult. There is a “black hole” once containers arrive at the destination port. Again, processes such as Destination Management can help cure this.

2: Validate your container data

Disruptions that lead to detention and demurrage can also be reduced with better data validation. Expert destination managers scrubbing shipment and transport data such as master bills of lading for consistency and proper ETA’s (estimated time of arrival), terminal listings, arrival dates, and gate out dates. Container shipment data is notorious for lacking standards, being incomplete and inaccurate. Unintentional mistakes or missing information can delay shipments and add costs. Validating data ensures shippers have good data quality and shipments aren’t delayed or incur added costs.

In summary, shippers need a way and process to clean container shipment data flowing into their internal operations and transportation management systems (TMS).

3: Use Managed Services at Destination

Once containers reach the destination port and are unloaded from a vessel, having the manpower to act on real-time data is essential. Daily monitoring of this data tracks terminal availability for drayage services and enables the escalation of any exceptions to the terminal authority. With active container dwell management, demurrage charges are minimized. Additionally, by effectively managing drayage carriers, the on-time pick-up and delivery of full and empty containers is ensured. When internal team resources are limited, an organization is scaling fast, or lacking logistics expertise, Managed Service Teams can own these processes and provide immediate ROI.

The combination of freight technology, real-time data reporting, and managed logistics services is extremely effective and the way forward for many BCO’s (Beneficial Cargo Owners). Containers can move more efficiently and with greater velocity when Destination Management services are used that includes a team of knowledgeable logistics professionals and visibility to all containers in transit.

The Good News: You Can Optimize Your Port Logistics at Destination

Time and time again, we find that businesses do not have the staff nor the connected supply chain visibility across the company or divisions. There is a lack of coordination of inbound containers and drayage partners, and container logistics reporting processes are weak or not in real time. They are using spreadsheets that are out of date minutes after they’re updated.

The answer to managing import containers is a more proactive approach using advanced hands-on management, clean data and visibility. It can be a tall order for importers to achieve. Most are not set up with the right technology or expertise to address endless challenges, but the rewards are great. By streamlining data, partnering with logistics experts and leveraging innovative technologies, companies can experience an unbroken flow of container logistics data that offers a more effective way for importers to manage inventory, control freight costs, and forecast and plan.